A handful of nice chinese mold component machining manufacturers images I found:

Producers

Cool Mold Producers In China pictures

Verify out these mold producers in china pictures:

Gun and Splint

Image by failing_angel

Assault Rifle AK-47, 1945-7

Designer: Mikhail Kalashnikov (1919-2013)

Manufacturer: unknown, China

This simple to use, inexpensive to produce, Soviet design is the most broadly utilised weapon in the planet. It is popularwith soldiers for its robust qualities that enables it to function, with no jamming or overheating below intense situations, sustaining exemplary reliability. The forged steel and wood or plywood design and style weighs just more than 4kg.

Leg splint, 1942

Designer: Charles Eames (1907-78) and Ray Eames (1912-88)

Manufacture: Evans Products, Moulded Plywood Division, USA

During World War II, Charles and Ray Eames created a lightweight but rigid leg splint for the US Navy. Used to transport the wounded, the inexpensive, mass-produced plywood designed replaced the prior metal version a material then in brief provide. The encounter of experimenting with moulded plywood production led the Eames’s to design and style of a series of influential plywood furnishings.

[Design and style Museum]

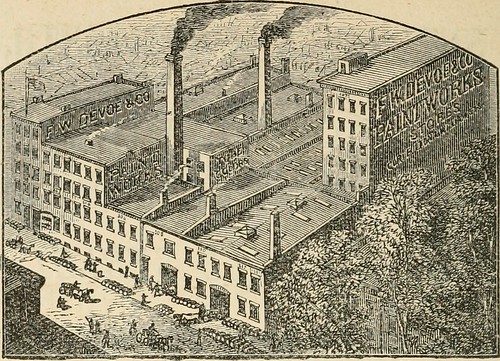

Image from page 241 of “Reputable cook book” (1878)

Image by Internet Archive Book Images

Identifier: reliablecookbook00sill

Title: Reliable cook book

Year: 1878 (1870s)

Authors: Silleck, Willie, Miss., [from old catalog] comp

Subjects: Cookery, American cbk

Publisher: New York, D. H. Gildersleeve & co., printers

Contributing Library: The Library of Congress

Digitizing Sponsor: Sloan Foundation

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Pictures: All Photos From Book

Click here to view book on the web to see this illustration in context in a browseable on-line version of this book.

Text Appearing Just before Image:

No. ten WALL STREET, Will give careful interest to the Purcliase and Sale of STOCKS, BONDS OR GOLD, on commission, generating advances on exact same when preferred. EDWARD MILLER & CO. B 5 No. 35 WARREN STREET, Cor. Church Street, NEW YORK.

Text Appearing Right after Image:

Paint Operates : Horatio and Jane Streets, New York. ARTISTS Materials. F. & CO.. Oor* Fulton a.n«l WilliaiiB «tsi«, New ITork, manUVacturees ofARTISTS OIL COLORS, IN TUBES CANVAS, ACADEMY BOARDS, MILLBOARDS, ANDOIL-SKETCHING PAPERS Fine Brushes for Oil and Water Colour Painting. Varnishes, Water Colour Liquids, Oils, And so forth. Drawiiig Papers, Sketching Books and Blocks, Pencils, Mathematical Instruments, Charcoal and Crayon Drawing Components, Illustrated Books on Art, Folding and Studio Easels,Drawing Boards, Studies, Manikins and Lay-Figures, Out-of-door Sketching Boxes.WINSOR & NEWTONSCAKE AN» MOIST AVATER COLORS,Tube Colors, Canvas, and so forth. also, French and GermanGoods.SCULPTORS TOOLS, MODELING WAX AND CLAY. PLASTER CASTS FOR MODELS.ANTIQUE POTTERY AND PORCELAIN TILES, with components for Pottery and China Decoration.Fresco Desigus aud Colora, aud Brushes for Fresco aud Scenic rainting. WAX FLOWER SUPPLIES : COLORS, TOOLS, MOULDS AND BRUSHES. Companies of WHITE LEAD, ZINO W

Note About Pictures

Please note that these pictures are extracted from scanned page images that may have been digitally enhanced for readability – coloration and appearance of these illustrations may possibly not completely resemble the original function.

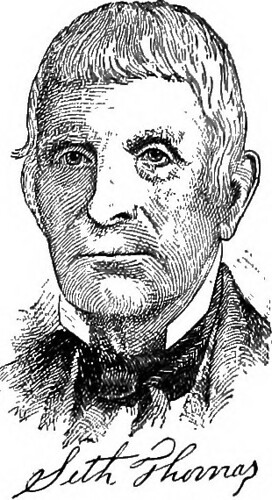

Image from page 139 of “The National cyclopædia of American biography : getting the history of the United States as illustrated in the lives of the founders, builders, and defenders of the republic, and of the guys and women who are undertaking the perform and mouldi

Image by Net Archive Book Photos

Identifier: cu31924020334755

Title: The National cyclopædia of American biography : being the history of the United States as illustrated in the lives of the founders, builders, and defenders of the republic, and of the guys and ladies who are carrying out the work and moulding the thought of the present time, edited by distinguished biographers, chosen from each state, revised and approved by the most eminent historians, scholars, and statesmen of the day

Year: 1893 (1890s)

Authors: Derby, George White, James Terry, 1845-1920

Subjects:

Publisher: New York : J. T. White firm

Contributing Library: Cornell University Library

Digitizing Sponsor: MSN

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Photos: All Photos From Book

Click here to view book on-line to see this illustration in context in a browseable on the internet version of this book.

Text Appearing Ahead of Image:

lyhe favored the whig celebration religiou,sly he was aCongregationalist and contributed largely to thebuilding of the present Congregational church edi-fice of Thomaston. He was twice married: very first toPhilena Tuttle, daughter of Lemuel and Lydia Tut-tle, Apr. 20, 1808. She died March 12, 1810. Hewas married on Apr. 14, 1811, to Laura Andrews,daughter of William and Submit Andrews. Shedied July 12, 1871. He was the father of nine chil-dren, 3 of whom died in September, 1815, in theyear memorable as that of the dysentery scourge.He died Jan. 29, 1859. THOMAS, Seth, manufacturer, was bom at Ply-mouth Hollow, Conn., Dec. 31, 1816, son of SethThomas. He enlarged and made great improve-ments in his father s factory, and introduced theSeth Thomas clocks into all parts of the globe, in-cluding the remote nations of China and Japan.He prided himself on having created every kind of time-piece from the most delicate watch to a town clock.He died at his residence in Thomaston, Conn., Apr.28, 1888.

Text Appearing Right after Image:

OF AMERICAN BIOGRAPHY. 119

Note About Images

Please note that these images are extracted from scanned page pictures that might have been digitally enhanced for readability – coloration and look of these illustrations may not completely resemble the original operate.

Image from web page 166 of “The manufacture of rubber goods : a sensible handbook for the use of producers, chemists, and other folks” (1919)

A couple of good mould companies in china photos I identified:

Image from web page 166 of “The manufacture of rubber goods : a sensible handbook for the use of producers, chemists, and other people” (1919)

Image by Net Archive Book Photos

Identifier: manufactureofrub00heil

Title: The manufacture of rubber goods : a sensible handbook for the use of manufacturers, chemists, and other individuals

Year: 1919 (1910s)

Authors: Heil, Adolf Esch, W. (Werner), b. 1878 Lewis, Edward W. (Edward Watkin)

Subjects: Rubber Rubber business and trade

Publisher: London : C. Griffin & Company

Contributing Library: Claire T. Carney Library, University of Massachusetts Dartmouth

Digitizing Sponsor: Claire T. Carney Library, University of Massachusetts Dartmouth

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Photos: All Pictures From Book

Click here to view book online to see this illustration in context in a browseable on the web version of this book.

Text Appearing Just before Image:

ulcanised in French chalk, and subsequently reduce to the 1 See also the write-up , Kombinierte hydraulische Kesselpresse Id theGummi-Zeitung, 1905, vol. xix. p. 1001. MANUFACTURE OF SOFT-RUBBER ARTICLES. 155 appropriate size by means of an eccentric punch, holes being at thesame time punched in them. The matrix which holds the knifeand the punch can be adjusted to take all sizes. A single man canpunch on an typical 8000 flat pedals in a day. Curved brake-rubbers with a tough-rubber inner layer are run on the machine inthe two various qualities, joined with each other by means of remedy,reduce up into pieces of the appropriate size, and vulcanised in Frenchchalk. The curved surface is buffed into shape on the lathe, bymeans of a shaped emery-wheel. Complex rubbers must bemade up and vulcanised in moulds. Strong bicycle-tyres are run on the tube machine and then vulcan-ised in moulds (fig. 70) under the hydraulic vulcanising press, endlesstyres getting created in suitable closed moulds, as also are cushion tyres.

Text Appearing Soon after Image:

Fig. 70. Perambulator tyres are also machined, and are then joined up andvulcanised in chalk in the open, or in moulds beneath the press. 9. Manufacture of Soft-Rubber Surgical Goods, and so on.—The manu-facture of air-cushions, water-cushions, mattresses, hot-water bottles,and also of gas-bags, constitutes one more division of the sector,to which it is now proposed to direct the readers attention. The 3 chief variables for good results in this branch are: (1) clean,dense mixings, free of charge from grit (2) calendered sheet of uniformthickness, and fabric closely proofed (3) cautious hand labour. The mixings in most frequent use are white ones. For cushions, e.g., the following mixings could be suggested:— Mozambique . ten,000 gras. China-clay 3,500 gms Sulphur . 1,200 „ Ceresin . 200 „ Zinc white . . six,500 ,, Magnesia usta. 200 „ The mixing is in component run into lengths of doubled sheet on thecalenders, and made up into cushions with cloth-impression and in 156 RUBBER MANUFACTURE. part produced

Note About Photos

Please note that these photos are extracted from scanned page images that could have been digitally enhanced for readability – coloration and appearance of these illustrations may possibly not completely resemble the original perform.

Greatest Plastic Merchandise Producers

Inside China, Plastic-kind material Market place has now considered a amazing step, while plastic-type goods are typically common throughout difficult drive & Components Managing Merchandise, Cast Pieces of furnishings, Car Pieces Manufacturing Cast Merchandise, Electronics goods in addition to Safety Presentation Merchandise and so forth. Plastics Marketplace in China, beginning with the actual generation of distinct every day essential plastic-type goods. Since then, is growing in addition to diversified at the great rate. Nowadays, the actual Indian native Plastics Marketplace is really spread in the China since Plastic-kind material is in fact essential in every facet of contemporary existence. Research show that it is amongst the most encouraging exporters amongst establishing countries with regards to plastic goods makers.

A lot of the important Plastic-type material Item that The far east today exports abroad is in fact Garbage, Client Goods, Sanitary Fittings, Development Merchandise, Presentation Goods and lots of a lot much more. Everyone expects finest in addition to price-effective system presently so simply because of this, we have presented below a listing of effectively-identified plastic items companies in addition to Businesses, whom completely grasp in addition to adjust to your distinct apprehension.

Influenced by means of superior information along with knowledgeable labor force, fortunately they are weighed down along with infrastructural amenities. Individuals are crucial for your finalizing connected with high grade connected with Plastic Solutions for example Plastic Connect, Plastic Particles Shelves along with UV Repellent Polycarbonate Safeguard Covers. In ask by means of our own clientele, they also create customized options like customized Plastic Mouldings along with Tailored Plastic Genuine estate Options. That they keep any encouraging price tag insurance coverage program, in arrears which typically, majority order placed are generally invited variety your clientele.

Many men and women strive to exceed client’s expectations by means of providing them an array of plastic-kind material goods, industrial plastic-type material goods, plastic goods, plastic-variety material goods makers, Wright plastic-sort material goods, rotocasting plastic-sort material goods, Plastic-type material Textile Films, Stainless Films, as well as other Residence Appliances and other house connected products. Made in an eco-friendly setting, they tend to be place on & rip immune along with meet the prerequisites involving property business. Garbage which can be located in the actual generating of these goods tends to be just looked at by means of your superb pros. This specific assures the actual output involving extended lasting along with faultless goods.

There’re supported by a group involving skilled analysts, which frequently emerge employing new concepts & recommendations. These concepts along with recommendations are used by way of your output pros to boost the caliber of your goods. His or her output experts adhere to outstanding managing plan to reassure which the end merchandise is in conjunction making use of explained sector specifications.

Today, they have got mustered an enormous consumers with countrywide together with intercontinental market place spot on account of your streamlined enterprise operations along with customer-centric tactic.

If there is any type of requirement of plastic merchandise for any goal, you may possibly order them from spark-mould.com

Associated Plastic Mould Companies In China Articles

Good Mold Producers In China photos

A few nice mold producers in china pictures I identified:

Spread the Word! – Save Jobs.

Image by Hasenpfeffer Incorporated

We make and sells dolls, teddy bears, and such. But this isn’t a plug for our organization. As a reaction to the dangerous-toy scare last year, the Consumer Solution Security Commission designed one thing called the Customer Merchandise Security Improvement Act. It needs all producers of children’s goods to submit their products for testing for lead and phthalates.

While that is good in the general scheme, it has some potentially damaging side effects. The issue is that the typical testing fee runs a few thousand dollars. Creating matters worse, we would have to submit each and every single toy for testing since no two are alike (she makes her stuff from salvaged materials like old wool coats and such). Naturally you can see what this version of the act would do to the handmade toy and craft market (it is much more than macramé owls nowadays).

There is a possible remedy, although. Below is the unabridged copy from the Handmade Handmade Toy Alliance. Beneath are hyperlinks to a sample letter and to numerous legislators.

Save the USA from the CPSIA

In 2007, large toy producers who outsource their production to China and other establishing countries violated the public’s trust. They had been promoting toys with dangerously higher lead content material, toys with unsafe little element, toys with improperly secured and simply swallowed tiny magnets, and toys produced from chemical substances that made youngsters sick. Nearly each and every problem toy in 2007 was produced in China.

The United States Congress rightly recognized that the Customer Products Safety Commission (CPSC) lacked the authority and staffing to avert hazardous toys from being imported into the US. So it passed the Consumer Product Safety Improvement Act (CPSIA) in August, 2008. Amongst other items, the CPSIA bans lead and phthalates in toys, mandates third-celebration testing and certification for all toys and calls for toy makers to permanently label every single toy with a date and batch number.

All of these alterations will be relatively simple for huge, multinational toy makers to comply with. Large companies who make thousands of units of every toy have extremely tiny incremental cost to spend for testing and update their molds to include batch labels.

For small American, Canadian, and European toymakers, even so, the costs of mandatroy testing will likely drive them out of business.

* A toymaker, for instance, who tends to make wooden vehicles in his garage in Maine to supplement his income cannot afford the ,000 charge per toy that testing labs are charging to assure compliance with the CPSIA.

* A perform at property mom in Minnesota who tends to make dolls to sell at craft fairs must select either to violate the law or cease operations.

* A modest toy retailer in Vermont who imports wooden toys from Europe, which has extended had stringent toy safety requirements, have to now pay for testing on each toy they import.

* And even the handful of bigger toy makers who nonetheless employ workers in the United States face elevated fees to comply with the CPSIA, even although American-produced toys had nothing at all to do with the toy safety problems of 2007.

The CPSIA merely forgot to exclude the class of toys that have earned and kept the public’s trust: Toys produced in the US, Canada, and Europe. The outcome, unless the law is modified, is that handmade toys will no longer be legal in the US.

If this law had been applied to the meals industry, each and every farmers market place in the country would be forced to close while Kraft and Dole prospered.

How You can Help:

Please create to your United States Congress Particular person and Senator to request modifications in the CPSIA to save handmade toys. Use our sample letter or write your personal. You can find your Congress Individual here and Senator here.

Thank you so significantly!

Most recent Injection Mould Producers In China News

Artists and Makers Say Goodbye to Sanding & Hello to Glossy 3D Prints with …

This sort of craftsmanship was begun in the 13th century in China and demands skill and an clearly really steady hand—as properly as a smooth surface to accommodate the fine brush strokes. While her hands may possibly bear the talent brought forth … We've been …

Read much more on 3DPrint.com

Data Systems Consulting, Techmation kind strategic cooperation to tap China …

Enterprise resource organizing (ERP) resolution provider Data Systems Consulting and Techmation, a developer of automated manage systems for plastic injection molding machinery, on April 26 signed a strategic cooperation agreement to market automated …

Study far more on Digitimes

Most recent Plastic Mould Producers In China News

Why Melbourne is the design capital of Australia

Right after travelling to Tianjin, China, the exhibition tends to make its prodigal return as element of Understanding Week. "Melbourne can … From the ute to the Kambrook power board, the exhibition represents 165 years of style and innovation across automotive, medical …

Read a lot more on The Age

Style and substance, from waste

Concrete will be crushed and washed to make cement kerbs, hollow bricks and manufactured sand. Plastic and wood will be sent for … The components he used in building include rubble from landfills, fly ash, discarded wooden crates, glass and …

Read much more on The Hindu

Cool Injection Molded Plastic Producers China images

Check out these injection molded plastic manufacturers china images:

Steven F. Udvar-Hazy Center: P-38 Lightning, with B-29 Enola Gay behind it

Image by Chris Devers

See more photos of this, and the Wikipedia article.

Details, quoting from Smithsonian National Air and Space Museum | Lockheed P-38J-10-LO Lightning

In the P-38 Lockheed engineer Clarence "Kelly" Johnson and his team of designers created one of the most successful twin-engine fighters ever flown by any nation. From 1942 to 1945, U. S. Army Air Forces pilots flew P-38s over Europe, the Mediterranean, and the Pacific, and from the frozen Aleutian Islands to the sun-baked deserts of North Africa. Lightning pilots in the Pacific theater downed more Japanese aircraft than pilots flying any other Allied warplane.

Maj. Richard I. Bong, America’s leading fighter ace, flew this P-38J-10-LO on April 16, 1945, at Wright Field, Ohio, to evaluate an experimental method of interconnecting the movement of the throttle and propeller control levers. However, his right engine exploded in flight before he could conduct the experiment.

Transferred from the United States Air Force.

Manufacturer:

Lockheed Aircraft Company

Date:

1943

Country of Origin:

United States of America

Dimensions:

Overall: 390 x 1170cm, 6345kg, 1580cm (12ft 9 9/16in. x 38ft 4 5/8in., 13988.2lb., 51ft 10 1/16in.)

Materials:

All-metal

Physical Description:

Twin-tail boom and twin-engine fighter; tricycle landing gear.

Long Description:

From 1942 to 1945, the thunder of P-38 Lightnings was heard around the world. U. S. Army pilots flew the P-38 over Europe, the Mediterranean, and the Pacific; from the frozen Aleutian Islands to the sun-baked deserts of North Africa. Measured by success in combat, Lockheed engineer Clarence "Kelly" Johnson and a team of designers created the most successful twin-engine fighter ever flown by any nation. In the Pacific Theater, Lightning pilots downed more Japanese aircraft than pilots flying any other Army Air Forces warplane.

Johnson and his team conceived this twin-engine, single-pilot fighter airplane in 1936 and the Army Air Corps authorized the firm to build it in June 1937. Lockheed finished constructing the prototype XP-38 and delivered it to the Air Corps on New Year’s Day, 1939. Air Corps test pilot and P-38 project officer, Lt. Benjamin S. Kelsey, first flew the aircraft on January 27. Losing this prototype in a crash at Mitchel Field, New York, with Kelsey at the controls, did not deter the Air Corps from ordering 13 YP-38s for service testing on April 27. Kelsey survived the crash and remained an important part of the Lightning program. Before the airplane could be declared ready for combat, Lockheed had to block the effects of high-speed aerodynamic compressibility and tail buffeting, and solve other problems discovered during the service tests.

The most vexing difficulty was the loss of control in a dive caused by aerodynamic compressibility. During late spring 1941, Air Corps Major Signa A. Gilke encountered serious trouble while diving his Lightning at high-speed from an altitude of 9,120 m (30,000 ft). When he reached an indicated airspeed of about 515 kph (320 mph), the airplane’s tail began to shake violently and the nose dropped until the dive was almost vertical. Signa recovered and landed safely and the tail buffet problem was soon resolved after Lockheed installed new fillets to improve airflow where the cockpit gondola joined the wing center section. Seventeen months passed before engineers began to determine what caused the Lightning’s nose to drop. They tested a scale model P-38 in the Ames Laboratory wind tunnel operated by the NACA (National Advisory Committee for Aeronautics) and found that shock waves formed when airflow over the wing leading edges reached transonic speeds. The nose drop and loss of control was never fully remedied but Lockheed installed dive recovery flaps under each wing in 1944. These devices slowed the P-38 enough to allow the pilot to maintain control when diving at high-speed.

Just as the development of the North American P-51 Mustang, Republic P-47 Thunderbolt, and the Vought F4U Corsair (see NASM collection for these aircraft) pushed the limits of aircraft performance into unexplored territory, so too did P-38 development. The type of aircraft envisioned by the Lockheed design team and Air Corps strategists in 1937 did not appear until June 1944. This protracted shakedown period mirrors the tribulations suffered by Vought in sorting out the many technical problems that kept F4U Corsairs off U. S. Navy carrier decks until the end of 1944.

Lockheed’s efforts to trouble-shoot various problems with the design also delayed high-rate, mass production. When Japan attacked Pearl Harbor, the company had delivered only 69 Lightnings to the Army. Production steadily increased and at its peak in 1944, 22 sub-contractors built various Lightning components and shipped them to Burbank, California, for final assembly. Consolidated-Vultee (Convair) subcontracted to build the wing center section and the firm later became prime manufacturer for 2,000 P-38Ls but that company’s Nashville plant completed only 113 examples of this Lightning model before war’s end. Lockheed and Convair finished 10,038 P-38 aircraft including 500 photo-reconnaissance models. They built more L models, 3,923, than any other version.

To ease control and improve stability, particularly at low speeds, Lockheed equipped all Lightnings, except a batch ordered by Britain, with propellers that counter-rotated. The propeller to the pilot’s left turned counter-clockwise and the propeller to his right turned clockwise, so that one propeller countered the torque and airflow effects generated by the other. The airplane also performed well at high speeds and the definitive P-38L model could make better than 676 kph (420 mph) between 7,600 and 9,120 m (25,000 and 30,000 ft). The design was versatile enough to carry various combinations of bombs, air-to-ground rockets, and external fuel tanks. The multi-engine configuration reduced the Lightning loss-rate to anti-aircraft gunfire during ground attack missions. Single-engine airplanes equipped with power plants cooled by pressurized liquid, such as the North American P-51 Mustang (see NASM collection), were particularly vulnerable. Even a small nick in one coolant line could cause the engine to seize in a matter of minutes.

The first P-38s to reach the Pacific combat theater arrived on April 4, 1942, when a version of the Lightning that carried reconnaissance cameras (designated the F-4), joined the 8th Photographic Squadron based in Australia. This unit launched the first P-38 combat missions over New Guinea and New Britain during April. By May 29, the first 25 P-38s had arrived in Anchorage, Alaska. On August 9, pilots of the 343rd Fighter Group, Eleventh Air Force, flying the P-38E, shot down a pair of Japanese flying boats.

Back in the United States, Army Air Forces leaders tried to control a rumor that Lightnings killed their own pilots. On August 10, 1942, Col. Arthur I. Ennis, Chief of U. S. Army Air Forces Public Relations in Washington, told a fellow officer "… Here’s what the 4th Fighter [training] Command is up against… common rumor out there that the whole West Coast was filled with headless bodies of men who jumped out of P-38s and had their heads cut off by the propellers." Novice Lightning pilots unfamiliar with the correct bailout procedures actually had more to fear from the twin-boom tail, if an emergency dictated taking to the parachute but properly executed, Lightning bailouts were as safe as parachuting from any other high-performance fighter of the day. Misinformation and wild speculation about many new aircraft was rampant during the early War period.

Along with U. S. Navy Grumman F4F Wildcats (see NASM collection) and Curtiss P-40 Warhawks (see NASM collection), Lightnings were the first American fighter airplanes capable of consistently defeating Japanese fighter aircraft. On November 18, men of the 339th Fighter Squadron became the first Lightning pilots to attack Japanese fighters. Flying from Henderson Field on Guadalcanal, they claimed three during a mission to escort Boeing B-17 Flying Fortress bombers (see NASM collection).

On April 18, 1943, fourteen P-38 pilots from the 70th and the 339th Fighter Squadrons, 347th Fighter Group, accomplished one of the most important Lightning missions of the war. American ULTRA cryptanalysts had decoded Japanese messages that revealed the timetable for a visit to the front by the commander of the Imperial Japanese Navy, Admiral Isoroku Yamamoto. This charismatic leader had crafted the plan to attack Pearl Harbor and Allied strategists believed his loss would severely cripple Japanese morale. The P-38 pilots flew 700 km (435 miles) at heights from 3-15 m (10-50 feet) above the ocean to avoid detection. Over the coast of Bougainville, they intercepted a formation of two Mitsubishi G4M BETTY bombers (see NASM collection) carrying the Admiral and his staff, and six Mitsubishi A6M Zero fighters (see NASM collection) providing escort. The Lightning pilots downed both bombers but lost Lt. Ray Hine to a Zero.

In Europe, the first Americans to down a Luftwaffe aircraft were Lt. Elza E. Shahan flying a 27th Fighter Squadron P-38E, and Lt. J. K. Shaffer flying a Curtiss P-40 (see NASM collection) in the 33rd Fighter Squadron. The two flyers shared the destruction of a Focke-Wulf Fw 200C-3 Condor maritime strike aircraft over Iceland on August 14, 1942. Later that month, the 1st fighter group accepted Lightnings and began combat operations from bases in England but this unit soon moved to fight in North Africa. More than a year passed before the P-38 reappeared over Western Europe. While the Lightning was absent, U. S. Army Air Forces strategists had relearned a painful lesson: unescorted bombers cannot operate successfully in the face of determined opposition from enemy fighters. When P-38s returned to England, the primary mission had become long-range bomber escort at ranges of about 805 kms (500 miles) and at altitudes above 6,080 m (20,000 ft).

On October 15, 1943, P-38H pilots in the 55th Fighter Group flew their first combat mission over Europe at a time when the need for long-range escorts was acute. Just the day before, German fighter pilots had destroyed 60 of 291 Eighth Air Force B-17 Flying Fortresses (see NASM collection) during a mission to bomb five ball-bearing plants at Schweinfurt, Germany. No air force could sustain a loss-rate of nearly 20 percent for more than a few missions but these targets lay well beyond the range of available escort fighters (Republic P-47 Thunderbolt, see NASM collection). American war planners hoped the long-range capabilities of the P-38 Lightning could halt this deadly trend, but the very high and very cold environment peculiar to the European air war caused severe power plant and cockpit heating difficulties for the Lightning pilots. The long-range escort problem was not completely solved until the North American P-51 Mustang (see NASM collection) began to arrive in large numbers early in 1944.

Poor cockpit heating in the H and J model Lightnings made flying and fighting at altitudes that frequently approached 12,320 m (40,000 ft) nearly impossible. This was a fundamental design flaw that Kelly Johnson and his team never anticipated when they designed the airplane six years earlier. In his seminal work on the Allison V-1710 engine, Daniel Whitney analyzed in detail other factors that made the P-38 a disappointing airplane in combat over Western Europe.

• Many new and inexperienced pilots arrived in England during December 1943, along with the new J model P-38 Lightning.

• J model rated at 1,600 horsepower vs. 1,425 for earlier H model Lightnings. This power setting required better maintenance between flights. It appears this work was not done in many cases.

• During stateside training, Lightning pilots were taught to fly at high rpm settings and low engine manifold pressure during cruise flight. This was very hard on the engines, and not in keeping with technical directives issued by Allison and Lockheed.

• The quality of fuel in England may have been poor, TEL (tetraethyl lead) fuel additive appeared to condense inside engine induction manifolds, causing detonation (destructive explosion of fuel mixture rather than controlled burning).

• Improved turbo supercharger intercoolers appeared on the J model P-38. These devices greatly reduced manifold temperatures but this encouraged TEL condensation in manifolds during cruise flight and increased spark plug fouling.

Using water injection to minimize detonation might have reduced these engine problems. Both the Republic P-47 Thunderbolt and the North American P-51 Mustang (see NASM collection) were fitted with water injection systems but not the P-38. Lightning pilots continued to fly, despite these handicaps.

During November 1942, two all-Lightning fighter groups, the 1st and the 14th, began operating in North Africa. In the Mediterranean Theater, P-38 pilots flew more sorties than Allied pilots flying any other type of fighter. They claimed 608 enemy a/c destroyed in the air, 123 probably destroyed and 343 damaged, against the loss of 131 Lightnings.

In the war against Japan, the P-38 truly excelled. Combat rarely occurred above 6,080 m (20,000 ft) and the engine and cockpit comfort problems common in Europe never plagued pilots in the Pacific Theater. The Lightning’s excellent range was used to full advantage above the vast expanses of water. In early 1945, Lightning pilots of the 12th Fighter Squadron, 18th Fighter Group, flew a mission that lasted 10 ½ hours and covered more than 3,220 km (2,000 miles). In August, P-38 pilots established the world’s long-distance record for a World War II combat fighter when they flew from the Philippines to the Netherlands East Indies, a distance of 3,703 km (2,300 miles). During early 1944, Lightning pilots in the 475th Fighter Group began the ‘race of aces.’ By March, Lieutenant Colonel Thomas J. Lynch had scored 21 victories before he fell to antiaircraft gunfire while strafing enemy ships. Major Thomas B. McGuire downed 38 Japanese aircraft before he was killed when his P-38 crashed at low altitude in early January 1945. Major Richard I. Bong became America’s highest scoring fighter ace (40 victories) but died in the crash of a Lockheed P-80 (see NASM collection) on August 6, 1945.

Museum records show that Lockheed assigned the construction number 422-2273 to the National Air and Space Museum’s P-38. The Army Air Forces accepted this Lightning as a P-38J-l0-LO on November 6, 1943, and the service identified the airplane with the serial number 42-67762. Recent investigations conducted by a team of specialists at the Paul E. Garber Facility, and Herb Brownstein, a volunteer in the Aeronautics Division at the National Air and Space Museum, have revealed many hitherto unknown aspects to the history of this aircraft.

Brownstein examined NASM files and documents at the National Archives. He discovered that a few days after the Army Air Forces (AAF) accepted this airplane, the Engineering Division at Wright Field in Dayton, Ohio, granted Lockheed permission to convert this P-38 into a two-seat trainer. The firm added a seat behind the pilot to accommodate an instructor who would train civilian pilots in instrument flying techniques. Once trained, these test pilots evaluated new Lightnings fresh off the assembly line.

In a teletype sent by the Engineering Division on March 2, 1944, Brownstein also discovered that this P-38 was released to Colonel Benjamin S. Kelsey from March 3 to April 10, 1944, to conduct special tests. This action was confirmed the following day in a cable from the War Department. This same pilot, then a Lieutenant, flew the XP-38 across the United States in 1939 and survived the crash that destroyed this Lightning at Mitchel Field, New York. In early 1944, Kelsey was assigned to the Eighth Air Force in England and he apparently traveled to the Lockheed factory at Burbank to pick up the P-38. Further information about these tests and Kelsey’s involvement remain an intriguing question.

One of Brownstein’s most important discoveries was a small file rich with information about the NASM Lightning. This file contained a cryptic reference to a "Major Bong" who flew the NASM P-38 on April 16, 1945, at Wright Field. Bong had planned to fly for an hour to evaluate an experimental method of interconnecting the movement of the throttle and propeller control levers. His flight ended after twenty-minutes when "the right engine blew up before I had a chance [to conduct the test]." The curator at the Richard I. Bong Heritage Center confirmed that America’s highest scoring ace made this flight in the NASM P-38 Lightning.

Working in Building 10 at the Paul E. Garber Facility, Rob Mawhinney, Dave Wilson, Wil Lee, Bob Weihrauch, Jim Purton, and Heather Hutton spent several months during the spring and summer of 2001 carefully disassembling, inspecting, and cleaning the NASM Lightning. They found every hardware modification consistent with a model J-25 airplane, not the model J-10 painted in the data block beneath the artifact’s left nose. This fact dovetails perfectly with knowledge uncovered by Brownstein. On April 10, the Engineering Division again cabled Lockheed asking the company to prepare 42-67762 for transfer to Wright Field "in standard configuration." The standard P-38 configuration at that time was the P-38J-25. The work took several weeks and the fighter does not appear on Wright Field records until May 15, 1944. On June 9, the Flight Test Section at Wright Field released the fighter for flight trials aimed at collecting pilot comments on how the airplane handled.

Wright Field’s Aeromedical Laboratory was the next organization involved with this P-38. That unit installed a kit on July 26 that probably measured the force required to move the control wheel left and right to actuate the power-boosted ailerons installed in all Lightnings beginning with version J-25. From August 12-16, the Power Plant Laboratory carried out tests to measure the hydraulic pump temperatures on this Lightning. Then beginning September 16 and lasting about ten days, the Bombing Branch, Armament Laboratory, tested type R-3 fragmentation bomb racks. The work appears to have ended early in December. On June 20, 1945, the AAF Aircraft Distribution Office asked that the Air Technical Service Command transfer the Lightning from Wright Field to Altus Air Force Base, Oklahoma, a temporary holding area for Air Force museum aircraft. The P-38 arrived at the Oklahoma City Air Depot on June 27, 1945, and mechanics prepared the fighter for flyable storage.

Airplane Flight Reports for this Lightning also describe the following activities and movements:

6-21-45 Wright Field, Ohio, 5.15 hours of flying.

6-22-45Wright Field, Ohio, .35 minutes of flying by Lt. Col. Wendel [?] J. Kelley and P. Shannon.

6-25-45Altus, Oklahoma, .55 hours flown, pilot P. Shannon.

6-27-45Altus, Oklahoma, #2 engine changed, 1.05 hours flown by Air Corps F/O Ralph F. Coady.

10-5-45 OCATSC-GCAAF (Garden City Army Air Field, Garden City, Kansas), guns removed and ballast added.

10-8-45Adams Field, Little Rock, Arkansas.

10-9-45Nashville, Tennessee,

5-28-46Freeman Field, Indiana, maintenance check by Air Corps Capt. H. M. Chadhowere [sp]?

7-24-46Freeman Field, Indiana, 1 hour local flight by 1st Lt. Charles C. Heckel.

7-31-46 Freeman Field, Indiana, 4120th AAF Base Unit, ferry flight to Orchard Place [Illinois] by 1st Lt. Charles C. Heckel.

On August 5, 1946, the AAF moved the aircraft to another storage site at the former Consolidated B-24 bomber assembly plant at Park Ridge, Illinois. A short time later, the AAF transferred custody of the Lightning and more than sixty other World War II-era airplanes to the Smithsonian National Air Museum. During the early 1950s, the Air Force moved these airplanes from Park Ridge to the Smithsonian storage site at Suitland, Maryland.

• • •

Quoting from Wikipedia | Lockheed P-38 Lightning:

The Lockheed P-38 Lightning was a World War II American fighter aircraft built by Lockheed. Developed to a United States Army Air Corps requirement, the P-38 had distinctive twin booms and a single, central nacelle containing the cockpit and armament. Named "fork-tailed devil" by the Luftwaffe and "two planes, one pilot" by the Japanese, the P-38 was used in a number of roles, including dive bombing, level bombing, ground-attack, photo reconnaissance missions, and extensively as a long-range escort fighter when equipped with drop tanks under its wings.

The P-38 was used most successfully in the Pacific Theater of Operations and the China-Burma-India Theater of Operations as the mount of America’s top aces, Richard Bong (40 victories) and Thomas McGuire (38 victories). In the South West Pacific theater, the P-38 was the primary long-range fighter of United States Army Air Forces until the appearance of large numbers of P-51D Mustangs toward the end of the war. The P-38 was unusually quiet for a fighter, the exhaust muffled by the turbo-superchargers. It was extremely forgiving, and could be mishandled in many ways, but the rate of roll was too slow for it to excel as a dogfighter. The P-38 was the only American fighter aircraft in production throughout American involvement in the war, from Pearl Harbor to Victory over Japan Day.

Variants: Lightning in maturity: P-38J

The P-38J was introduced in August 1943. The turbo-supercharger intercooler system on previous variants had been housed in the leading edges of the wings and had proven vulnerable to combat damage and could burst if the wrong series of controls were mistakenly activated. In the P-38J model, the streamlined engine nacelles of previous Lightnings were changed to fit the intercooler radiator between the oil coolers, forming a "chin" that visually distinguished the J model from its predecessors. While the P-38J used the same V-1710-89/91 engines as the H model, the new core-type intercooler more efficiently lowered intake manifold temperatures and permitted a substantial increase in rated power. The leading edge of the outer wing was fitted with 55 gal (208 l) fuel tanks, filling the space formerly occupied by intercooler tunnels, but these were omitted on early P-38J blocks due to limited availability.

The final 210 J models, designated P-38J-25-LO, alleviated the compressibility problem through the addition of a set of electrically-actuated dive recovery flaps just outboard of the engines on the bottom centerline of the wings. With these improvements, a USAAF pilot reported a dive speed of almost 600 mph (970 km/h), although the indicated air speed was later corrected for compressibility error, and the actual dive speed was lower. Lockheed manufactured over 200 retrofit modification kits to be installed on P-38J-10-LO and J-20-LO already in Europe, but the USAAF C-54 carrying them was shot down by an RAF pilot who mistook the Douglas transport for a German Focke-Wulf Condor. Unfortunately the loss of the kits came during Lockheed test pilot Tony LeVier‘s four-month morale-boosting tour of P-38 bases. Flying a new Lightning named "Snafuperman" modified to full P-38J-25-LO specs at Lockheed’s modification center near Belfast, LeVier captured the pilots’ full attention by routinely performing maneuvers during March 1944 that common Eighth Air Force wisdom held to be suicidal. It proved too little too late because the decision had already been made to re-equip with Mustangs.

The P-38J-25-LO production block also introduced hydraulically-boosted ailerons, one of the first times such a system was fitted to a fighter. This significantly improved the Lightning’s rate of roll and reduced control forces for the pilot. This production block and the following P-38L model are considered the definitive Lightnings, and Lockheed ramped up production, working with subcontractors across the country to produce hundreds of Lightnings each month.

Noted P-38 pilots

Richard Bong and Thomas McGuire

The American ace of aces and his closest competitor both flew Lightnings as they tallied 40 and 38 victories respectively. Majors Richard I. "Dick" Bong and Thomas J. "Tommy" McGuire of the USAAF competed for the top position. Both men were awarded the Medal of Honor.

McGuire was killed in air combat in January 1945 over the Philippines, after racking up 38 confirmed kills, making him the second-ranking American ace. Bong was rotated back to the United States as America’s ace of aces, after making 40 kills, becoming a test pilot. He was killed on 6 August 1945, the day the atomic bomb was dropped on Japan, when his P-80 Shooting Star jet fighter flamed out on takeoff.

Charles Lindbergh

The famed aviator Charles Lindbergh toured the South Pacific as a civilian contractor for United Aircraft Corporation, comparing and evaluating performance of single- and twin-engined fighters for Vought. He worked to improve range and load limits of the F4U Corsair, flying both routine and combat strafing missions in Corsairs alongside Marine pilots. In Hollandia, he attached himself to the 475th FG flying P-38s so that he could investigate the twin-engine fighter. Though new to the machine, he was instrumental in extending the range of the P-38 through improved throttle settings, or engine-leaning techniques, notably by reducing engine speed to 1,600 rpm, setting the carburetors for auto-lean and flying at 185 mph (298 km/h) indicated airspeed which reduced fuel consumption to 70 gal/h, about 2.6 mpg. This combination of settings had been considered dangerous; it was thought it would upset the fuel mixture and cause an explosion. Everywhere Lindbergh went in the South Pacific, he was accorded the normal preferential treatment of a visiting colonel, though he had resigned his Air Corps Reserve colonel’s commission three years before. While with the 475th, he held training classes and took part in a number of Army Air Corps combat missions. On 28 July 1944, Lindbergh shot down a Mitsubishi Ki-51 "Sonia" flown expertly by the veteran commander of 73rd Independent Flying Chutai, Imperial Japanese Army Captain Saburo Shimada. In an extended, twisting dogfight in which many of the participants ran out of ammunition, Shimada turned his aircraft directly toward Lindbergh who was just approaching the combat area. Lindbergh fired in a defensive reaction brought on by Shimada’s apparent head-on ramming attack. Hit by cannon and machine gun fire, the "Sonia’s" propeller visibly slowed, but Shimada held his course. Lindbergh pulled up at the last moment to avoid collision as the damaged "Sonia" went into a steep dive, hit the ocean and sank. Lindbergh’s wingman, ace Joseph E. "Fishkiller" Miller, Jr., had also scored hits on the "Sonia" after it had begun its fatal dive, but Miller was certain the kill credit was Lindbergh’s. The unofficial kill was not entered in the 475th’s war record. On 12 August 1944 Lindbergh left Hollandia to return to the United States.

Charles MacDonald

The seventh-ranking American ace, Charles H. MacDonald, flew a Lightning against the Japanese, scoring 27 kills in his famous aircraft, the Putt Putt Maru.

Robin Olds

Main article: Robin Olds

Robin Olds was the last P-38 ace in the Eighth Air Force and the last in the ETO. Flying a P-38J, he downed five German fighters on two separate missions over France and Germany. He subsequently transitioned to P-51s to make seven more kills. After World War II, he flew F-4 Phantom IIs in Vietnam, ending his career as brigadier general with 16 kills.

Clay Tice

A P-38 piloted by Clay Tice was the first American aircraft to land in Japan after VJ-Day, when he and his wingman set down on Nitagahara because his wingman was low on fuel.

Antoine de Saint-Exupéry

Noted aviation pioneer and writer Antoine de Saint-Exupéry vanished in a F-5B-1-LO, 42-68223, c/n 2734, of Groupe de Chasse II/33, out of Borgo-Porreta, Bastia, Corsica, a reconnaissance variant of the P-38, while on a flight over the Mediterranean, from Corsica to mainland France, on 31 July 1944. His health, both physical and mental (he was said to be intermittently subject to depression), had been deteriorating and there had been talk of taking him off flight status. There have been suggestions (although no proof to date) that this was a suicide rather than an aircraft failure or combat loss. In 2000, a French scuba diver found the wreckage of a Lightning in the Mediterranean off the coast of Marseille, and it was confirmed in April 2004 as Saint-Exupéry’s F-5B. No evidence of air combat was found. In March 2008, a former Luftwaffe pilot, Horst Rippert from Jagdgruppe 200, claimed to have shot down Saint-Exupéry.

Adrian Warburton

The RAF’s legendary photo-recon "ace", Wing Commander Adrian Warburton DSO DFC, was the pilot of a Lockheed P-38 borrowed from the USAAF that took off on 12 April 1944 to photograph targets in Germany. W/C Warburton failed to arrive at the rendezvous point and was never seen again. In 2003, his remains were recovered in Germany from his wrecked USAAF P-38 Lightning.

• • • • •

Quoting Smithsonian National Air and Space Museum | Boeing B-29 Superfortress "Enola Gay":

Boeing’s B-29 Superfortress was the most sophisticated propeller-driven bomber of World War II and the first bomber to house its crew in pressurized compartments. Although designed to fight in the European theater, the B-29 found its niche on the other side of the globe. In the Pacific, B-29s delivered a variety of aerial weapons: conventional bombs, incendiary bombs, mines, and two nuclear weapons.

On August 6, 1945, this Martin-built B-29-45-MO dropped the first atomic weapon used in combat on Hiroshima, Japan. Three days later, Bockscar (on display at the U.S. Air Force Museum near Dayton, Ohio) dropped a second atomic bomb on Nagasaki, Japan. Enola Gay flew as the advance weather reconnaissance aircraft that day. A third B-29, The Great Artiste, flew as an observation aircraft on both missions.

Transferred from the United States Air Force.

Manufacturer:

Boeing Aircraft Co.

Martin Co., Omaha, Nebr.

Date:

1945

Country of Origin:

United States of America

Dimensions:

Overall: 900 x 3020cm, 32580kg, 4300cm (29ft 6 5/16in. x 99ft 1in., 71825.9lb., 141ft 15/16in.)

Materials:

Polished overall aluminum finish

Physical Description:

Four-engine heavy bomber with semi-monoqoque fuselage and high-aspect ratio wings. Polished aluminum finish overall, standard late-World War II Army Air Forces insignia on wings and aft fuselage and serial number on vertical fin; 509th Composite Group markings painted in black; "Enola Gay" in black, block letters on lower left nose.

Latest Injection Mold Producers China News

MacBook Rumors: Apple Pushes for Larger, Thinner Lineup?

In a post, 9to5 Mac hinted that the organization is set to do "some spring cleaning" in order to make way for its new machines. The internet site … The said ultra-thin MacBooks will reportedly "adopt metal injection molding-produced (MIM) hinges," according to Digitimes.

Study a lot more on ChinaTopix